Add to Cart

Mixed particle size SPD030 PCD blanks with good wear resistance

Product Manual

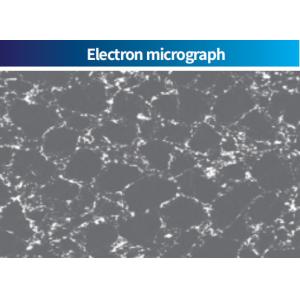

The diamond crystals in the diamond layer of PCD are disorderly arranged, isotropic,

without cleavage surfaces, and have high hardness, high wear resistance, and high thermal

the conductivity of diamond; the cemented carbide layer as the base has high impact toughness

and Solderability. Therefore, PCD is particularly suitable for cutting tools of non-ferrous metals

and non-metallic materials and supporting wear parts of various instruments and equipment.

Feature

The mixed particle size has extremely high wear resistance, good impact resistance, and thermal stability.

Application

Suitable for high hardness non-ferrous metal alloys (such as high silicon aluminum alloy,

cemented carbide), graphite.

Processing of glass fiber, ceramics, composite flooring, and other materials.

| Model | Diameter | Diamond layer | Total thickness±0.05mm) | ||||

| mm | thickness(±0.1mm) | 1.0 | 1.2 | 1.6 | 2.0 | 3.2 | |

| SPD005 | 55 | 0.5/0.9/1.2 | √ | √ | √ | √ | √ |

| SPD010 | 55 | 0.5/0.9/1.2 | √ | √ | √ | √ | √ |

| SPD030 | 55 | 0.5/0.9/1.2 | √ | √ | √ | √ | √ |

| SPD010W | 55 | 0.3/0.5/0.9 | √ | √ | √ | √ | √ |

| Our company can provide customized products according to customer needs | |||||||

As an experienced PCD blanks supplier, our company also provides diamond die blanks,

diamond saw blades, diamond cutting tools, and CVD diamond products, among others.

We also offer laser cutting service of PCBN blank, and we are committed to providing our

customers with cost-effective, high-performance, and high-standard products.

About us: