Add to Cart

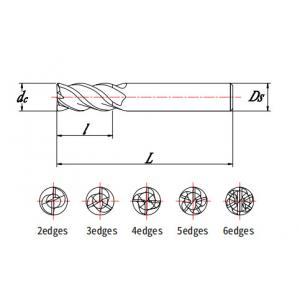

Cermet End Mill Solid Carbide Ceramic tools for Carbon steel, stainless steel

DESCRIPTION

Compared with cemented carbide tools, ceramic tools are more resistant to high

temperatures and can achieve dry cutting, which not only saves costs but also is

environmentally friendly; Good oxidation resistance makes it possible to realize

high-speed cutting and improved production efficiency; Ceramic tools do not need

coating, and can be used directly after CNC grinding

SPECIFICATION

The friction coefficient of the cermet end mill is small, and it is easier to achieve

higher surface quality when cutting steel parts.

| Materials suitable for processing | Carbon steel, stainless steel |

| Milling form | Side milling, shoulder milling, cavity milling, etc. |

| Blade diameter dc (mm) | 3~32 |

| Blade length (l mm) | 5~100 |

| Total length L (mm) | 38~200 |

| Shank diameter Ds (mm) | 4~32 |

| Handle form | Cylindrical shank |

| Number of blades | 2 edge, 3 edge, 4 edge, 5 edge, 6 edge |

| other | The blade can be designed to shrink, avoid air, taper, etc. |

About us: